Conservation of a Boulle Marquetry Bracket Clock

Conservation:

(as defined by the American Institute for Conservation) “The profession devoted to the preservation of cultural property for the future. Conservation activities include examination, documentation, treatment, and preventive care, supported by research and education.”

The technique of veneering a combination of metal and horn, tortoiseshell, ivory, or mother-of-pearl onto a wood substrate was a highly refined method of surface decoration employed during the late seventeenth and early eighteenth centuries in Europe. The procedure, which is a type of marquetry, was first developed in medieval Italy, where a combination of copper and the shell of the greenback turtle were used, primarily in the decoration of architectural forms. It was in France, during the reign of Louis XIV, that the technique was refined to its most artistic levels. By the seventeenth century, artisans such as Pierre Golle (France), J. D. Sommer (Germany), and Gerreit Jensen (England) contributed to making the practice accepted as a technique for decorating furniture. However, the French ébéniste André-Charles Boulle (1642–1732), is recognized as the principle and most accomplished practitioner. As a result of his prolific and inspired work, the terms “boulle work” or “boulle marquetry” are used to describe this type of furniture decoration.

The process, while varying in complexity, materials, and technique, basically consists of gluing together thin sheets of metal, such as brass or pewter, and animal components, such as tortoiseshell or ivory, and then cutting them into fanciful arrangements of geometric, arabesque and grotesque designs that are in turn glued onto a wood substrate. Due to the completely different properties of the materials and their opposite reactions to heat, cold, and relative humidity, it is not unusual for veneers to lift off their surface. Chemicals used in household brass polishing solutions can also pose problems; they can cause the glue to deteriorate, while polishing cloths can catch on the metal and pull it out of place. As such, examples of early boulle work have rarely escaped repair, restoration, or conservation.

A Louis XV clock dating to the mid-eighteenth century (Figs. 1–8) serves to illustrate the complexity associated with the proper conservation of boulle work. For the method of conservation to be appropriate for the age of the clock, it was first necessary to determine the maker of the case and of the clock works, and the approximate date and place of their manufacture. This information also affects the monetary value of the clock, which would vary considerably based on the findings.

Due to the previously mentioned problems with multi-media surface decoration, eighteenth-century clocks of this type are somewhat rare. Boulle decoration remained in vogue in England and France through the mid- to late-nineteenth century, and most surviving examples date to this later time period. Manufacturing techniques and materials were vastly different from the mid 1700s to the mid 1800s, and understanding the variations is helpful in establishing this clock’s age. The metal mounts, for instance, are fire (or mercury) gilded brass. This dates the mounts to the eighteenth century because the procedure was outlawed during the French Revolution (1789–1799). Magnified views of the backsides and edges of the metal inlay show the irregular patterns of hand work—sawing, beating (or blanishing as it was called), and toothing— typical of eighteenth century craftsmanship, versus the machine rolled backsides and straight bandsaw cut edges typical of the nineteenth century.

The inside of the case bears the stamp of the French ébenisté Jean-Ettiene Marchand. The name of Francois Hoguet is engraved into the mechanism and is also located on the dial (Fig. 1). Research at the library database of The National Association of Watch and Clock Collectors identified that Marchand and Hoguet were contemporaries working in Paris in the mid- eighteenth century. With the evidence of eighteenth-century manufacture and the confirmation of two well know artisans of the period, conservation could proceed in the proper historic context. The mechanism was made and signed by Francois Hoguet, also of Paris, and is contemporary with the case. The major steps involved in the restoration of its boulle work surface are described below, demonstrating some of the more interesting challenges of such a project.

Figures 1 and 2 show the clock in its received condition. The substrate woods have separated at their joints and have expanded and contracted throughout, causing numerous areas of the boulle work to lift and separate, with complete losses in some areas. After labeling and removing the gilded mounts, the structure was stabilized by opening the joints, removing old glue and re-gluing. Next, the boulle work surfaces were cleaned of grime and the bent, twisted and severely loose pieces of shell and metal were removed and labeled. The bent or twisted metal was then straightened by either heating and clamping or lightly flattening with a protective covering and a tack hammer.

The lifting but partially attached shell and metal was next addressed. Traditionally, animal hide glue was used to adhere the shell and metal to the wood. Over time glue deteriorates and the shell and metal detach.

Two methods were used in the re-gluing process. First, the old glue was removed from the back sides of the brass, shell, and the wood substrate with dentil tools. Where the surface could be clamped, a cork-backed wooden caul was made to conform to the shape of the surface. Paste wax was applied to the area around the lifting material to keep the glue from adhering to it. Animal hide glue was mixed with a small amount of Venice turpentine to aid in adhesion. Wax paper was placed between the caul and the surface to keep the glue from adhering to the caul. Once dried and unclamped, the excess glue was removed using a small brush or Q-tip dampened with warm water.

On surfaces where clamping was not possible finely ground shellac was used as the adhesive. The surfaces were prepared in the same method as for the hide glue, and a small amount of alcohol was injected into the inlay cavity to hold the ground shellac in place (Fig. 3). For reapplying lifting metal, pressure was placed onto the metal with a dentil pick to hold it in place, while a small soldering iron was used to heat the metal, causing the shellac to melt. Care was taken not to overheat the metal which might cause the surrounding shell to burn. The shellac was then allowed to dry, forming an adhesive bond that held the metal in place. Once dry, the excess shellac was removed using alcohol on a Q-tip. The second method was to use heated hide glue to adhere the shell, holding it in place with dentil picks until the glue set.

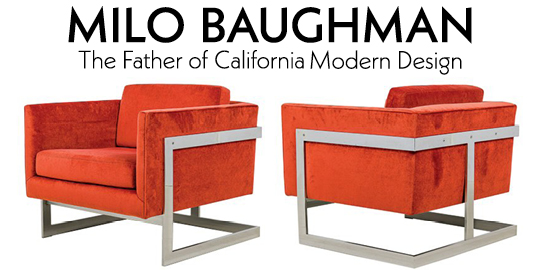

Patterns were made for the missing sections of metal and shell by using rubbings of the surface area and digital photographs matched in size. The photographs were printed on white paper and glued to 22-gauge brass sheets (Fig. 4) that were annealed to make them softer. Tiny holes were drilled along the outline to allow the insertion of a jeweler’s fret saw blade used to make the cuts. I like to back cut the replacement pieces of metal at about 10 degrees to give a better gluing surface at the edge, although this was not the method used on the piece originally. The variation also helps distinguish my work from the original.

It is illegal to purchase real tortoiseshell nowadays, but a number of synthetic substitutes are available. I prefer to use a reproduction shell made of a polymer. Variations in color between the original shell and the new material can be adjusted by toning the back side of the synthetic replacements before they are put into place.

Once cut, both brass and shell were glued into place (Fig. 5) using the same methods the original craftsmen used. The brass was “toothed” or scratched on the back to help adhesion. Minor areas of shell loss were filled by melting shellac which had been toned to approximate the color of the original shell into the spaces. The fill was then smoothed by lightly padding with an alcohol-dampened pad. The entire surface was then coated with a reversible conservation gloss varnish.

The final step of the project was to clean the metal mounts (Figs. 6, 7). Typical of eighteenth-century French furniture, the hardware on the clock was originally gilded with a solution of powdered gold and mercury spread on its cast brass and bronze pieces. The metal was then heated and the mercury vaporized, leaving a thin film of gold. This type of mount must be cleaned very carefully or the gold will be removed in the process. This was accomplished using a nonabrasive surfactant and Q-tips. Once cleaned, the hardware was coated with clear Agatine lacquer for protection. The mounts were reattached in their original positions, the glass cleaned and installed, and the doors reattached.

The final product (Fig. 8) is the result of approximately 175 hours of work, not including work on the clock’s mechanism, photography, research, or the final report. Conservation projects like this are very time consuming and therefore expensive. I recommend contacting the American Institute of Conservation [AIC], http://aic.stanford.edu, to find a conservator competent in this type of work.

-----

Rick Vogt, owner of F. C. Vogt Conservation (www.vogtconservation.com), Richmond, Virginia, wishes to thank conservation consultant Chris Swann of the Colonial Williamsburg Foundation, horologist Robert Draucker, The National Association of Watch and Clock Collectors, and Stuart Austin for their help with this project.

Photography courtesy of Katherine Wetzel and Teresa McMahon.